Lightweighting: The Key to Building the Vehicles of Tomorrow

How Lightweight Materials Are Improving the Performance and Efficiency of Vehicles.

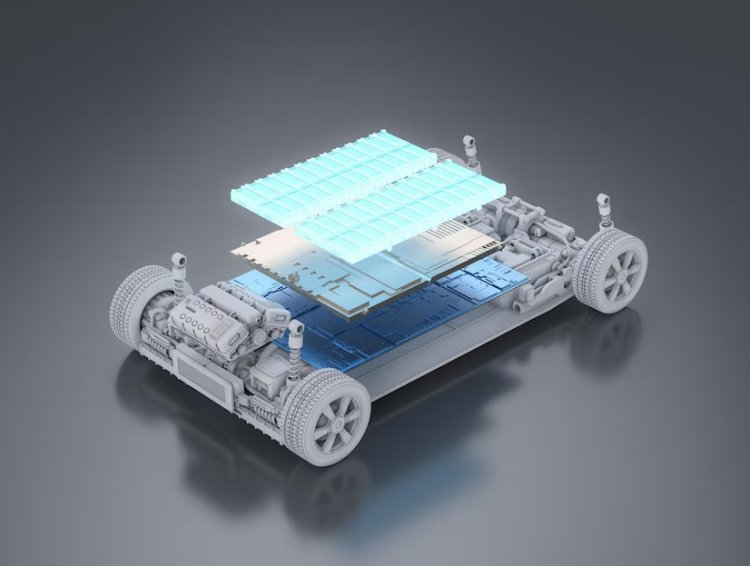

Lightweighting has been an essential part of automotive manufacturing for decades. With the rise of autonomous and electric vehicles, the need for lightweight materials is even more pressing. These vehicles require lighter weight to improve driving dynamics, range, and fuel efficiency.

There are a number of potential lightweight materials, including high-strength steel, aluminum, magnesium, titanium, composites, and lightweight plastics. However, the cost of each material varies depending on factors such as part complexity, part size, capital investment, additional labor, factory location, and reengineering effort.

The type of powertrain, production volumes, system integration, sustainability, and vehicle price will also influence the OEM's choice of lightweighting material. Ultimately, a part-specific strategy may be the best option, as each part has different requirements regarding formability, strength, and temperature resistance.

- The use of lightweight materials can help to reduce fuel consumption and emissions.

- Lightweight materials can also improve the safety of vehicles by making them more rigid and preventing them from collapsing in a crash.

- The development of new lightweight materials is an ongoing area of research, and there are a number of promising new materials that could be used in automotive manufacturing in the future.

Read more: royal-enfield-hunter-350-vs-triumph-speed-400

What's Your Reaction?